Mx200

A simple and innovative

readout solution for today’s

metrology marketplace.

*Supporting Keypad and Touchscreen control.

*Ideal for Optical Comparators, Measuring Microscopes, or any Metrology device requiring encoder supported measurement.

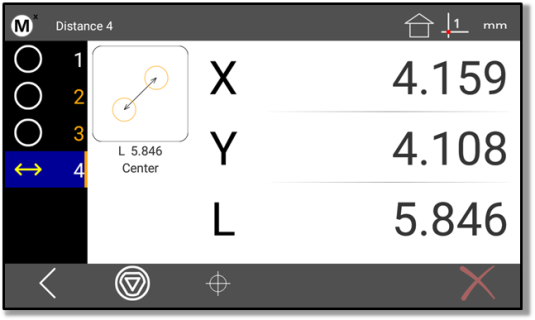

Clean, Intuitive Design

Combining a familiar user experience with current

touchscreen conventions, the Mx200 readout can

quickly be integrated into your process while

being accessible to a wide range of users.

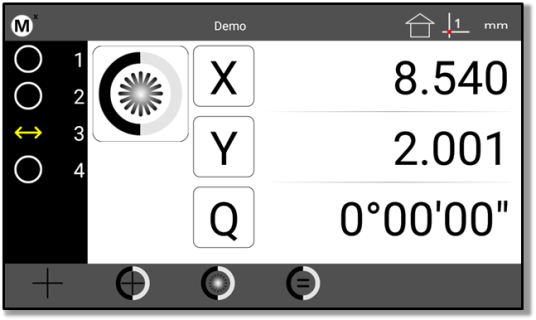

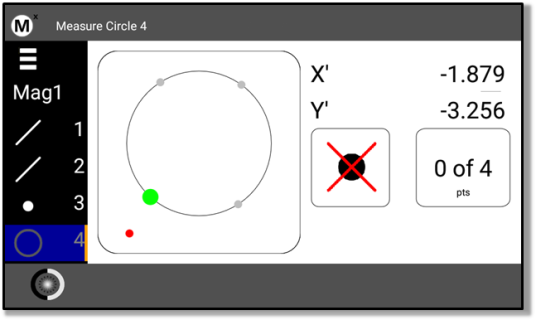

Optical Edge and Crosshair Probes

Available for both Optical Edge and Crosshair only measurement systems the Mx200 probing options are simple and intuitive. The exclusive EdgeLogic™ feature enables gesture driven control of start and end measurement commands, alleviating the need to interact with the DRO directly. Just cross the same edge twice to start and end measurements!

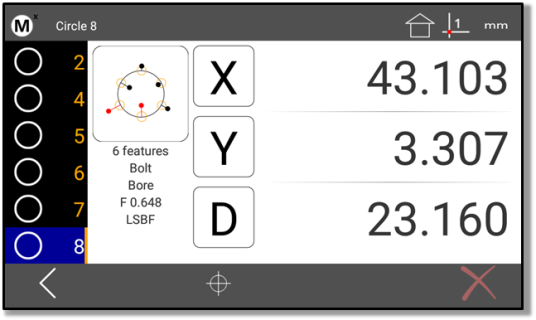

Features and Constructions

Supporting industry standard feature measurement and popular construction types. Toggle feature construction sub-types quickly with the change feature type button.

* Mid/Center Point * End Point Tangent Line

* Angle Compliments * Gage Circle/Line

* Intersections * Bolt Circle * Farthest Distance

* Perpendicular Lines * Shortest Distance

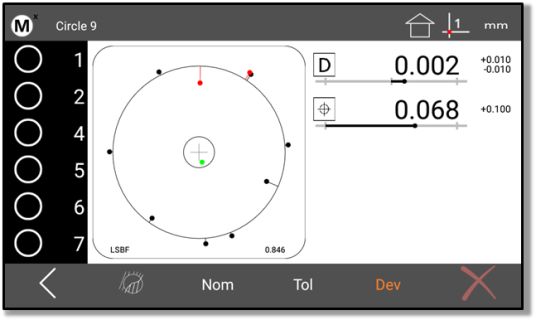

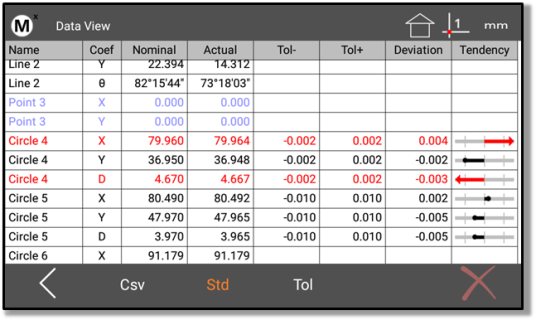

Geometric Tolerancing and Part Programming

Apply popular geometric tolerance controls to measured and

constructed features using the industry leading Metlogix tolerance

system. Apply nominal and tolerance limits quickly, and view

results accurately, in the large and easy to read data views.

Record inspection routines for simple playback of measurements, tolerance controls, and data handling and printing steps.

Report, Print, and Export

Choose from one of three report formats; CSV, Standard, or Tolerance. Report contents can include a report title, time and date stamps, and all feature measurement result data. Reports can be printed as hard copies to standard Windows compatible printers, or exported as PDF or CSV data files.

Export choices include:

* Paper Printer(USB, Wifi, Bluetooth)

* Save to file(USB)

* RS232 Output

Measuring Machine Integration

Ask your MetLogix representative about the wide variety of encoder interface technologies and other hardware supported in the Mx200 Digital Readout.

Support for All Current “Industry Standard”

Software Stage Calibration Methodologies

Robust and reliable machine calibration can be achieved using popular machine correction methods including Linear Error Correction(LEC), Segmented Linear Correction(SLEC), Non-Linear

Error Correction(NLEC), and squareness correction.

Robust and shop hardened digital readout

A sealed rubber keypad and durable powder coated

enclosure provide lasting performance and trouble free

operation in a variety of shop and laboratory conditions.

Mx200 Specifications:

Display: 7″ Color 1024 X 600 LCD, with an LED backlit capacitive touch screen.

Power: Power supply(included): 100-240VAC, 50/60Hz, 0.8A.

Power Input to Mx200: 12V.

Agency Approvals: CE

DRO Dimensions: 286mm wide x 51mm deep x 162 mm high

DRO Baseplate Dimensions: 120mm wide x 125mm deep x 9.5mm high

Mounting Options:

OEM mount: Two Riser Blocks providing up to 4 distinct

viewing angles, using (2) M6 threaded holes, spaced 38mm.

RAM ball mount: One Riser Block with 1.5” RAM Ball.

Base plate: Base Plate with two Riser Blocks providing up to

4 distinct viewing angles from the base.

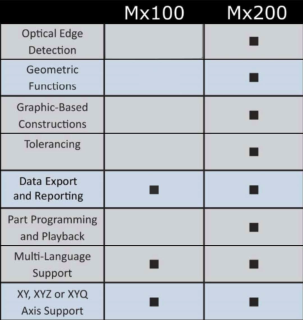

MetLogix Mx Series Features Matrix

Watch tutorial videos for popular Mx functions at

http://www.youtube.com/metlogix